In the world of modern visual communication, LED display screens have become crucial tools for broadcasting information. The quality and stability of these screens are paramount to ensuring effective communication. However, one persistent issue that has plagued the industry is the appearance of "bad pixels"—defective spots that negatively impact the visual experience.

The advent of GOB (Glue on Board) packaging technology has provided a solution to this problem, offering a revolutionary approach to enhancing display quality. This article explores how GOB packaging works and its role in addressing the bad pixel phenomenon.

1. What Are "Bad Pixels" in LED Displays?

"Bad pixels" refer to malfunctioning points on an LED display screen that cause noticeable irregularities in the image. These imperfections can take several forms:

- Bright Spots: These are overly bright pixels that appear as small light sources on the display. Typically, they manifest as white or sometimes colored spots that stand out against the background.

- Dark Spots: The opposite of bright spots, these areas are abnormally dark, almost blending into a dark screen, rendering them invisible unless viewed closely.

- Color Inconsistencies: In some cases, certain areas of the screen exhibit uneven colors, similar to the effect of paint spills, disrupting the smoothness of the display.

Causes of Bad Pixels

Bad pixels can be traced to several underlying factors:

- Manufacturing Defects: During the production of LED displays, dust, impurities, or poor-quality LED components may lead to pixel malfunctions. Additionally, poor handling or improper installation can also contribute to defective pixels.

- Environmental Factors: External elements such as static electricity, temperature fluctuations, and humidity can adversely affect the lifespan and performance of the LED display, potentially triggering pixel failure. For instance, a static discharge could damage the delicate circuitry or chip, leading to inconsistencies in pixel behavior.

- Aging and Wear: Over time, as LED displays are used continuously, their components can degrade. This aging process can cause the brightness and color fidelity of the pixels to diminish, giving rise to bad pixels.

2. Effects of Bad Pixels on LED Displays

The presence of bad pixels can have several negative impacts on LED displays, including:

- Decreased Visual Clarity: Just as an unreadable word in a book distracts a reader, bad pixels disrupt the viewing experience. Particularly on large displays, these pixels can significantly affect the clarity of important images, making the content less legible or aesthetically pleasing.

- Reduced Display Longevity: When a bad pixel appears, it signifies that a section of the screen is no longer functioning correctly. Over time, if these defective pixels accumulate, the overall lifespan of the display shortens.

- Negative Impact on Brand Image: For businesses relying on LED displays for advertisements or product showcases, a visible bad pixel can diminish the credibility of the brand. Customers may associate such flaws with poor quality or unprofessionalism, undermining the perceived value of the display and the business.

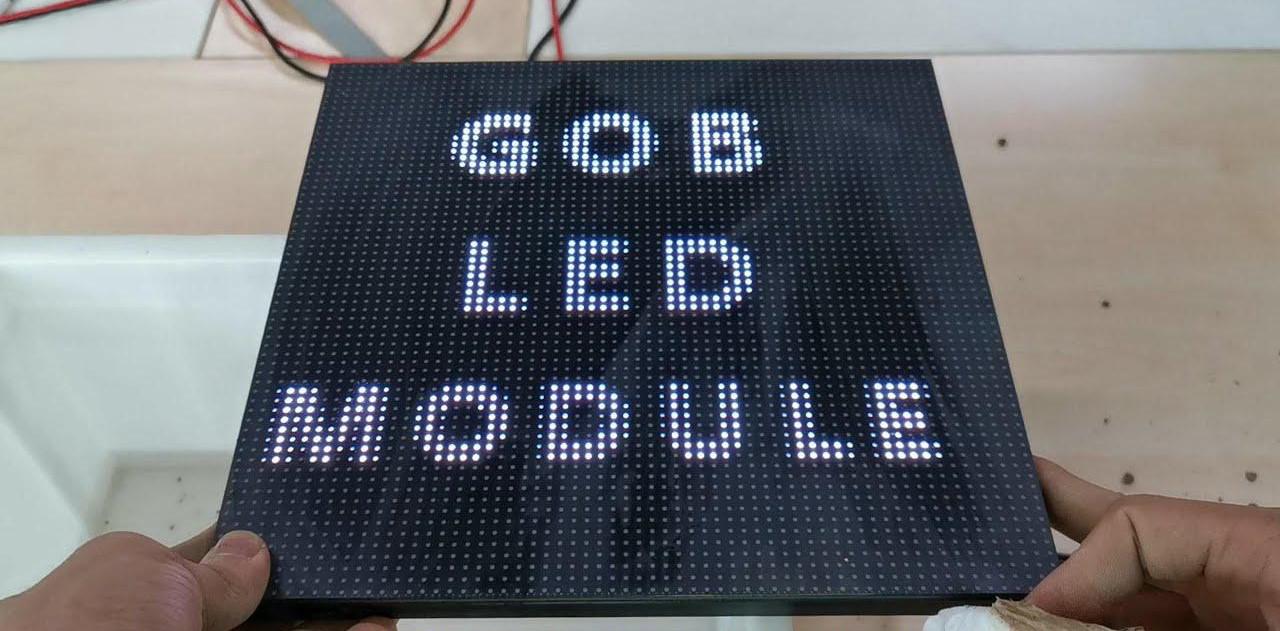

3. Introduction to GOB Packaging Technology

To address the persistent issue of bad pixels, GOB (Glue on Board) packaging technology was developed. This innovative solution involves attaching LED lamp beads to the circuit board and then filling the spaces between these beads with a specialized protective adhesive.

In essence, GOB packaging provides an extra layer of protection for the delicate LED components. Imagine the LED beads as small light bulbs that are exposed to external elements. Without proper protection, these components are susceptible to damage from moisture, dust, and even physical impact. The GOB method wraps these lamp beads in a layer of protective resin that shields them from such hazards.

Key Features of GOB Packaging Technology

- Enhanced Durability: The resin coating used in GOB packaging prevents the LED lamp beads from detaching, providing a more robust and stable display. This ensures the display's long-term reliability.

- Comprehensive Protection: The protective layer offers multi-faceted defense—it is waterproof, moisture-resistant, dustproof, and anti-static. This makes GOB technology an all-encompassing solution for protecting the display against environmental wear.

- Improved Heat Dissipation: One of the challenges of LED technology is the heat generated by the lamp beads. Excessive heat can cause the components to degrade, leading to bad pixels. The thermal conductivity of the GOB resin helps dissipate heat quickly, preventing overheating and prolonging the life of the lamp beads.

- Better Light Distribution: The resin layer also contributes to uniform light diffusion, improving the clarity and sharpness of the image. As a result, the display produces a clearer, more crisp image, free from distracting hot spots or uneven lighting.

Comparing GOB with Traditional LED Packaging Methods

To better understand the advantages of GOB technology, let’s compare it with other common packaging methods, such as SMD (Surface-Mounted Device) and COB (Chip on Board).

- SMD Packaging: In SMD technology, the LED beads are directly mounted onto the circuit board and soldered. While this method is relatively simple, it offers limited protection, leaving the LED beads vulnerable to damage. GOB technology enhances SMD by adding an extra layer of protective glue, increasing the resilience and longevity of the display.

- COB Packaging: COB is a more advanced method where the LED chip is directly attached to the board and encapsulated in resin. While this method offers high integration and uniformity in display quality, it is costly. GOB, on the other hand, provides superior protection and thermal management at a more affordable price point, making it an attractive option for manufacturers looking to balance performance with cost.

4. How GOB Packaging Eliminates "Bad Pixels"

GOB technology significantly reduces the occurrence of bad pixels through several key mechanisms:

- Precise and Streamlined Packaging: GOB eliminates the need for multiple layers of protective material by using a single, optimized layer of resin. This simplifies the manufacturing process while increasing the accuracy of the packaging, reducing the likelihood of positioning errors or defective installation that could lead to bad pixels.

- Reinforced Bonding: The adhesive used in GOB packaging has nano-level properties that ensure a tight bond between the LED lamp beads and the circuit board. This reinforcement ensures that the beads stay in place even under physical stress, reducing the likelihood of damage caused by impact or vibrations.

- Efficient Heat Management: The resin's excellent thermal conductivity helps regulate the temperature of the LED beads. By preventing excessive heat buildup, GOB technology extends the lifespan of the beads and minimizes the occurrence of bad pixels caused by thermal degradation.

- Easy Maintenance: If a bad pixel does occur, GOB technology facilitates quick and efficient repairs. Maintenance teams can easily identify the defective areas and replace the affected modules or beads without needing to replace the entire screen, thus reducing both downtime and repair costs.

5. The Future of GOB Technology

Despite its current success, GOB packaging technology is still evolving, and the future holds great promise. However, there are a few challenges to overcome:

- Continued Technological Refinement: As with any technology, GOB packaging must continue to improve. Manufacturers will need to refine the adhesive materials and filling processes to ensure the stability and reliability of the products.

- Cost Reduction: Currently, GOB technology is more expensive than traditional packaging methods. To make it accessible to a wider range of manufacturers, efforts must be made to reduce production costs, either through mass production or by optimizing the supply chain.

- Adaptation to Market Demands: The demand for higher-definition, smaller-pitch displays is increasing. GOB technology will need to evolve to meet these new requirements, offering greater pixel density and improved clarity without sacrificing durability.

- Integration with Other Technologies: The future of GOB may involve integration with other technologies, such as Mini/Micro LED and intelligent control systems. These integrations could further enhance the performance and versatility of LED displays, making them smarter and more adaptive to changing environments.

6. Conclusion

GOB packaging technology has proven to be a game-changer in the LED display industry. By providing enhanced protection, better heat dissipation, and precise packaging, it addresses the common issue of bad pixels, improving both the quality and reliability of displays. As GOB technology continues to evolve, it will play a crucial role in shaping the future of LED displays, driving higher-quality innovations and making the technology more accessible to a global market.

Post time: Dec-10-2024