Indoor SMD LED screens are now a dominant force in indoor display technology, particularly the small pitch varieties that are integral to settings such as conference rooms and control centers. Initially, these screens perform flawlessly, but over time, issues such as lamp failures can occur. Apart from natural wear and tear, factors like accidental impacts or improper handling during installation can also result in damage. Moist environments further exacerbate the risk of damage.

For these small pitch indoor LED screens, a rigorous check-up is necessary after at least six months to ensure their integrity. One of the pivotal challenges for LED screens manufacturers is addressing damage caused by moisture, dust, and physical impacts, while also enhancing product durability and minimizing maintenance costs. The introduction of GOB (Glue On Board) technology offers a promising solution.

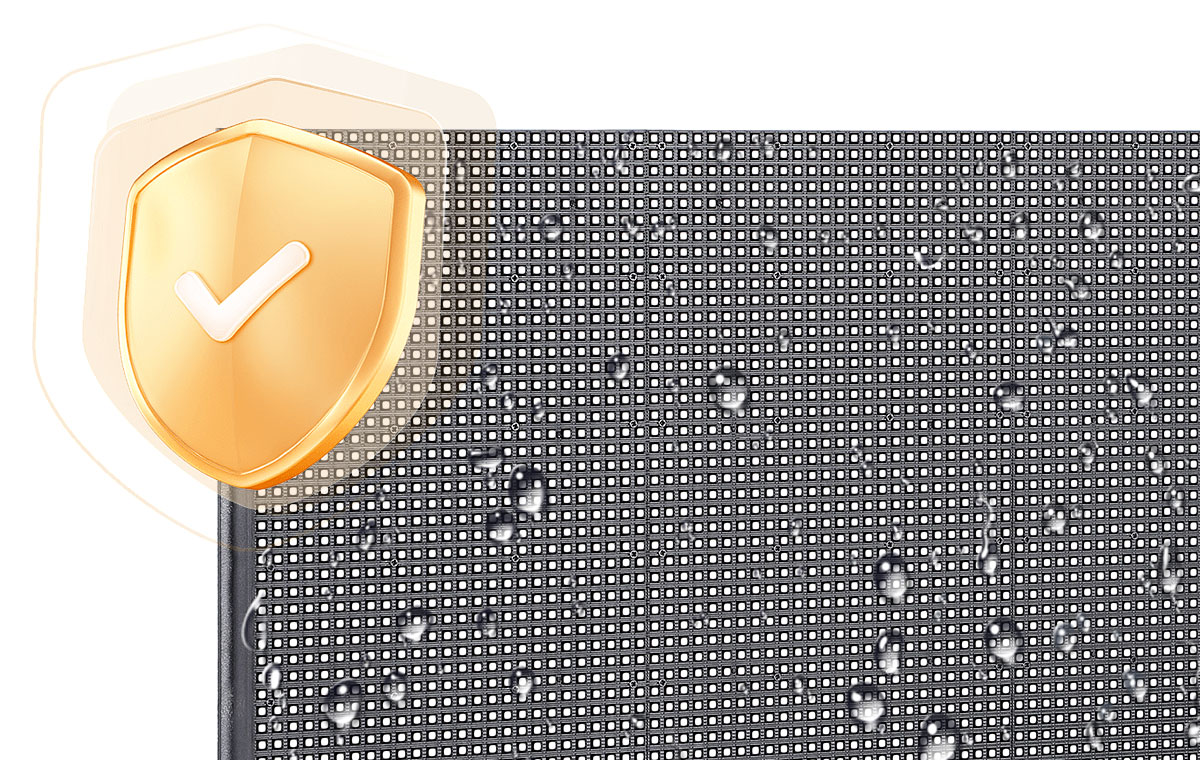

This innovative approach involves applying a layer of glue over the lamp board post a comprehensive 72-hour aging process. This not only shields the lamp base from moisture but also fortifies the screen against physical damage. While standard indoor LED screens typically have an IP40 rating, the GOB technology significantly boosts their ingress protection capabilities without drastically increasing costs, aligning well with market expectations and production feasibility.

The durability of the PCB board is not overlooked. It retains its robust three anti-paint protective processes. Enhancements include spraying the back of the PCB board to elevate protection levels and applying a coating over the IC's surface to safeguard the drive circuit's integrated circuit components from failure. This comprehensive approach ensures that both the front and the back of the LED screens are well-protected, extending their operational life and reliability.

Post time: Jun-06-2024