In modern electronic display technology, LED display is widely used in digital signage, stage background, indoor decoration and other fields because of its high brightness, high definition, long life and other advantages. In the manufacturing process of LED display, encapsulation technology is the key link. Among them, SMD encapsulation technology and COB encapsulation technology are two mainstream encapsulation. So, what is the difference between them? This article will provide you with an in-depth analysis.

1.what is SMD packaging technology, SMD packaging principle

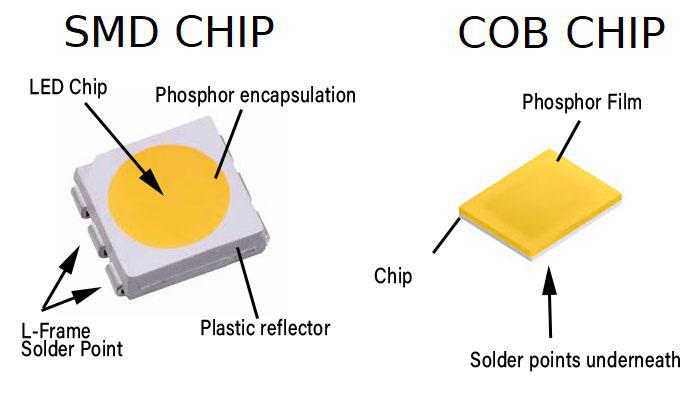

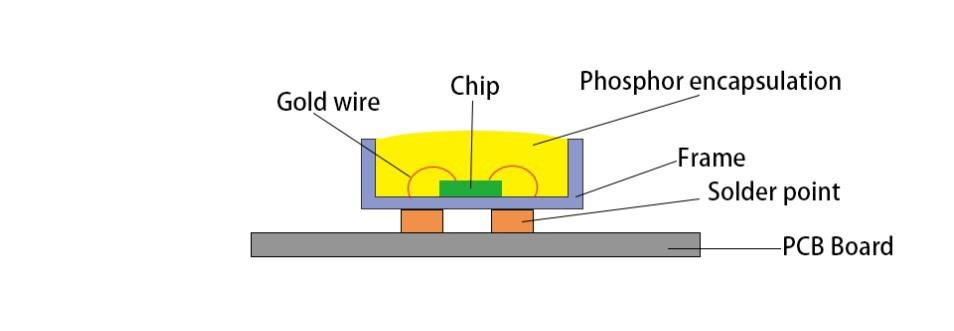

SMD package, full name Surface Mounted Device (Surface Mounted Device), is a kind of electronic components directly welded to the printed circuit board (PCB) surface packaging technology. This technology through the precision placement machine, the encapsulated LED chip (usually contains LED light-emitting diodes and the necessary circuit components) accurately placed on the PCB pads, and then through the reflow soldering and other ways to realize the electrical connection.SMD packaging technology makes the electronic components smaller, lighter in weight, and conducive to the design of more compact and lightweight electronic products.

2.The Advantages And Disadvantages Of SMD Packaging Technology

2.1 SMD Packaging Technology Advantages

(1) small size, light weight: SMD packaging components are small in size, easy to integrate high-density, conducive to the design of miniaturized and lightweight electronic products.

(2) good high-frequency characteristics: short pins and short connection paths help reduce inductance and resistance, improve high-frequency performance.

(3) Convenient for automated production: suitable for automated placement machine production, improve production efficiency and quality stability.

(4) Good thermal performance: direct contact with the PCB surface, conducive to heat dissipation.

2.2 SMD Packaging Technology Disadvantages

(1) relatively complex maintenance: although the surface mounting method makes it easier to repair and replace components, but in the case of high-density integration, the replacement of individual components may be more cumbersome.

(2) Limited heat dissipation area: mainly through the pad and gel heat dissipation, long time high load work may lead to heat concentration, affecting the service life.

3.what is COB packaging technology, COB packaging principle

COB package, known as Chip on Board (Chip on Board package), is a bare chip directly welded on the PCB packaging technology. The specific process is the bare chip (chip body and I/O terminals in the crystal above) with conductive or thermal adhesive bonded to the PCB, and then through the wire (such as aluminum or gold wire) in the ultrasonic, under the action of heat pressure, the chip's I/O terminals and the PCB pads are connected up, and finally sealed with resin adhesive protection. This encapsulation eliminates the traditional LED lamp bead encapsulation steps, making the package more compact.

4.The advantages and disadvantages of COB packaging technology

4.1 COB packaging technology advantages

(1) compact package, small size: eliminating the bottom pins, to achieve a smaller package size.

(2) superior performance: the gold wire connecting the chip and the circuit board, the signal transmission distance is short, reducing crosstalk and inductance and other issues to improve performance.

(3) Good heat dissipation: the chip is directly welded to the PCB, and heat is dissipated through the entire PCB board, and heat is easily dissipated.

(4) Strong protection performance: fully enclosed design, with waterproof, moisture-proof, dust-proof, anti-static and other protective functions.

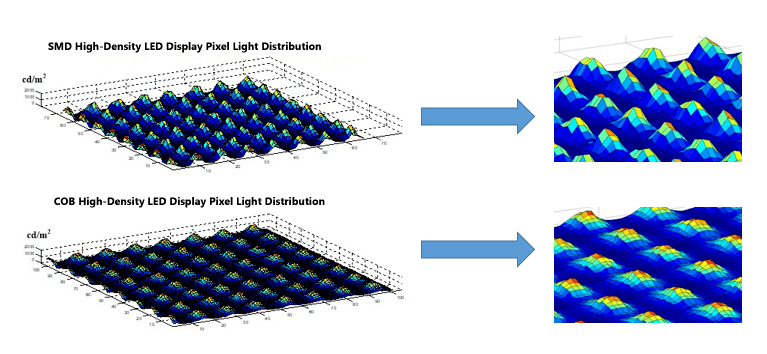

(5) good visual experience: as a surface light source, the color performance is more vivid, more excellent detail processing, suitable for long time close viewing.

4.2 COB packaging technology disadvantages

(1) maintenance difficulties: chip and PCB direct welding, can not be disassembled separately or replace the chip, maintenance costs are high.

(2) strict production requirements: the packaging process of environmental requirements are extremely high, does not allow dust, static electricity and other pollution factors.

5. The difference between SMD packaging technology and COB packaging technology

SMD encapsulation technology and COB encapsulation technology in the field of LED display each has its own unique features, the difference between them is mainly reflected in the encapsulation, size and weight, heat dissipation performance, ease of maintenance and application scenarios. The following is a detailed comparison and analysis:

5.1 Packaging method

⑴SMD packaging technology: the full name is Surface Mounted Device, which is a packaging technology that solders the packaged LED chip on the surface of the printed circuit board (PCB) through a precision patch machine. This method requires the LED chip to be packaged in advance to form an independent component and then mounted on the PCB.

⑵COB packaging technology: the full name is Chip on Board, which is a packaging technology that directly solders the bare chip on the PCB. It eliminates the packaging steps of traditional LED lamp beads, directly bonds the bare chip to the PCB with conductive or thermal conductive glue, and realizes electrical connection through metal wire.

5.2 Size and weight

⑴SMD packaging: Although the components are small in size, their size and weight are still limited due to packaging structure and pad requirements.

⑵COB package: Due to the omission of bottom pins and package shell, COB package achieves more extreme compactness, making the package smaller and lighter.

5.3 Heat dissipation performance

⑴SMD packaging: Mainly dissipates heat through pads and colloids, and the heat dissipation area is relatively limited. Under high brightness and high load conditions, heat may be concentrated in the chip area, affecting the life and stability of the display.

⑵COB package: The chip is directly welded on the PCB and heat can be dissipated through the entire PCB board. This design significantly improves the heat dissipation performance of the display and reduces the failure rate due to overheating.

5.4 Convenience of maintenance

⑴SMD packaging: Since the components are mounted independently on the PCB, it is relatively easy to replace a single component during maintenance. This is conducive to reducing maintenance costs and shortening maintenance time.

⑵COB packaging: Since the chip and PCB are directly welded into a whole, it is impossible to disassemble or replace the chip separately. Once a fault occurs, it is usually necessary to replace the entire PCB board or return it to the factory for repair, which increases the cost and difficulty of repair.

5.5 Application scenarios

⑴SMD packaging: Due to its high maturity and low production cost, it is widely used in the market, especially in projects that are cost-sensitive and require high maintenance convenience, such as outdoor billboards and indoor TV walls.

⑵COB packaging: Due to its high performance and high protection, it is more suitable for high-end indoor display screens, public displays, monitoring rooms and other scenes with high display quality requirements and complex environments. For example, in command centers, studios, large dispatch centers and other environments where staff watch the screen for a long time, COB packaging technology can provide a more delicate and uniform visual experience.

Conclusion

SMD packaging technology and COB packaging technology each have their own unique advantages and application scenarios in the field of LED display screens. Users should weigh and choose according to actual needs when choosing.

SMD packaging technology and COB packaging technology have their own advantages. SMD packaging technology is widely used in the market due to its high maturity and low production cost, especially in projects that are cost-sensitive and require high maintenance convenience. COB packaging technology, on the other hand, has strong competitiveness in high-end indoor display screens, public displays, monitoring rooms and other fields with its compact packaging, superior performance, good heat dissipation and strong protection performance.

Post time: Sep-20-2024